Crankshaft Bend; Oil Clearance between Crankpin and Crankpin Bearing- Page 235

Kubota L3560 Owners Manual

Table of Contents

ENGINE

L3560, L4060, L4760, L5060, L5460, L6060, WSM

1-S88

Crankshaft Bend

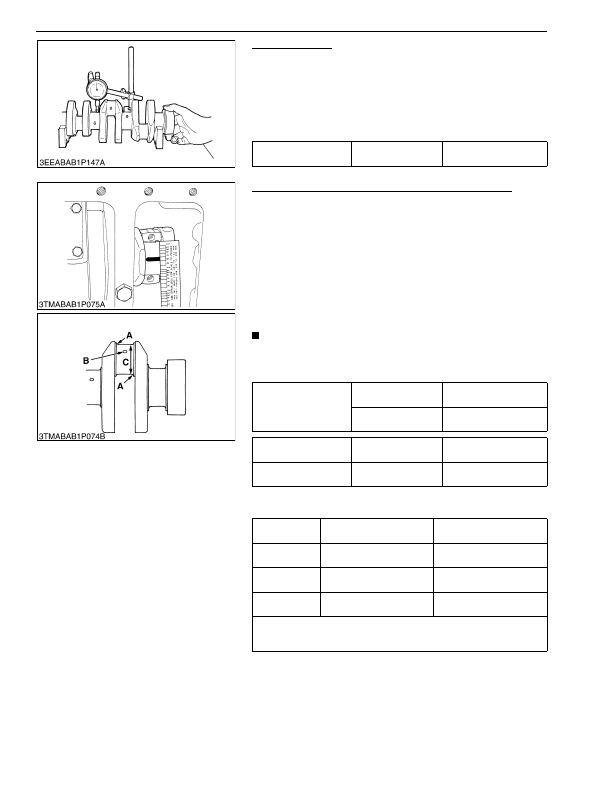

1. Hold the 2 end journals of crankshaft with V blocks on the

surface plate.

2. Set a dial indicator with its point on the middle journal.

3. Turn the crankshaft slowly and read the variation on the

indicator.

4. If the measurement is more than the allowable limit, replace the

crankshaft.

9Y1210824ENS0097US0

Oil Clearance between Crankpin and Crankpin Bearing

1. Clean the crankpin and crankpin bearing.

2. Put a strip of plastigauge on the center of the crankpin.

3. Install the connecting rod cap and tighten the connecting rod

screws to the specified torque, and remove the cap again.

4. Measure the width that it becomes flat with the scale to get the

oil clearance.

5. If the oil clearance is more than the allowable limit, replace the

crankpin bearing.

6. If the same dimension bearing is not applicable because of the

crankpin wear, replace it with an undersize one. Refer to the

table and figure.

NOTE

• Do not put the plastigauge into the crankpin oil hole.

• When you tighten the connecting rod screws, do not move

the crankshaft.

(Reference)

• Undersize dimensions of crankpin

9Y1210824ENS0098US0

Crankshaft bend

Allowable limit

0.03 mm

0.001 in.

Oil clearance between

crankpin and crankpin

bearing

Factory specification

0.025 to 0.087 mm

0.00099 to 0.0034 in.

Allowable limit

0.20 mm

0.0079 in.

Crankpin O.D.

Factory specification

46.959 to 46.975 mm

1.8488 to 1.8494 in.

Crankpin bearing I.D.

Factory specification

47.000 to 47.046 mm

1.8504 to 1.8522 in.

Undersize

0.2 mm

0.008 in.

0.4 mm

0.02 in.

Dimension

A

3.3 to 3.7 mm radius

0.13 to 0.14 in. radius

3.3 to 3.7 mm radius

0.13 to 0.14 in. radius

*Dimension

B

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

Dimension

C

46.759 to 46.775 mm dia.

1.8409 to 1.8415 in. dia.

46.559 to 46.575 mm dia.

1.8331 to 1.8336 in. dia.

The crankpin must be fine-finished to higher than Rmax = 0.4S

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.040 to 0.059 in.) relief.

KiSC issued 03, 2016 A

Detailed Information for Kubota L3560 Owners Manual

Lists of information found in Kubota L3560 Owners Manual - Page 235

- 1. Hold the 2 end journals of crankshaft with V blocks on the surface plate.

- 2. Set a dial indicator with its point on the middle journal.

- 3. Turn the crankshaft slowly and read the variation on the indicator.

- 4. If the measurement is more than the allowable limit, replace the crankshaft.

- 1. Clean the crankpin and crankpin bearing.

- 2. Put a strip of plastigauge on the center of the crankpin.

- 3. Install the connecting rod cap and tighten the connecting rod screws to the specified torque, and remove the cap again.

- 4. Measure the width that it becomes flat with the scale to get the oil clearance.

- 5. If the oil clearance is more than the allowable limit, replace the crankpin bearing.

- 6. If the same dimension bearing is not applicable because of the crankpin wear, replace it with an undersize one.

- 46.959 to 46.

- 1.8488 to 1.

- 47.000 to 47.

- 1.8504 to 1.

- 3.3 to 3.

- 3.3 to 3.

- 1.0 to 1.

- 1.0 to 1.

- 46.759 to 46.

- 1.8409 to 1.

- 46.559 to 46.

- 1.8331 to 1.

- 1.0 to 1.

- Do not put the plastigauge into the crankpin oil hole.

- When you tighten the connecting rod screws, do not move the crankshaft.

- Undersize dimensions of crankpin 9Y1210824ENS0098US0 Crankshaft bend Allowable limit 0.