7. SERVICING; [1] CYLINDER HEAD AND VALVES; Top Clearance- Page 223

Kubota L3560 Owners Manual

Table of Contents

ENGINE

L3560, L4060, L4760, L5060, L5460, L6060, WSM

1-S76

7. SERVICING

[1] CYLINDER HEAD AND VALVES

Top Clearance

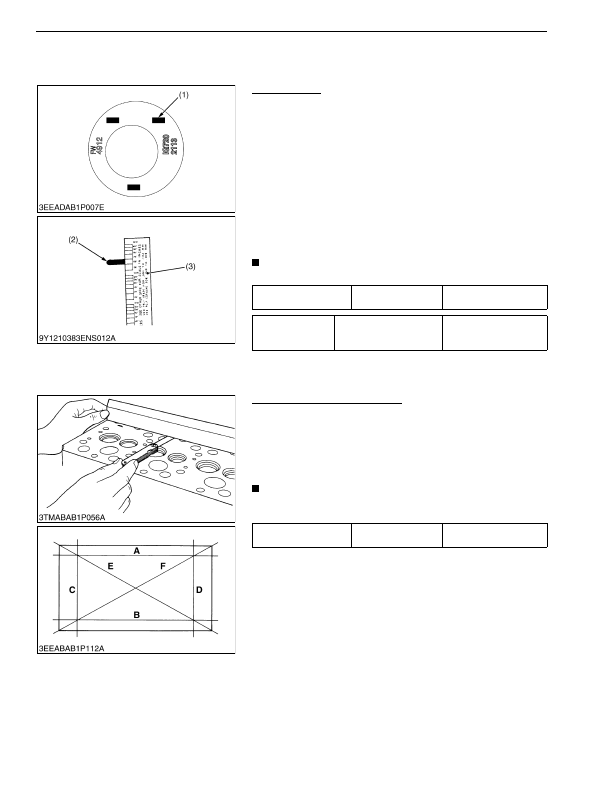

1. Remove the cylinder head.

2. With the piston at TDC, use grease to affix three or four

plastigauges (1) of a diameter 1.5 mm (0.059 in.) × 5.0 to

7.0 mm (0.20 to 0.27 in.) long to the crown of the piston; keep

the gauges away from the intake valve and combustion

chamber fittings.

3. Take the piston to an intermediate position, install the cylinder

head and tighten the head screws to the specified torque.

4. Turn the crankshaft so the piston goes through TDC.

5. Remove the cylinder head and compare the width of the

crushed plastigauges (2) with the scale (3).

6. If they are out of spec, check the oil clearance of the crank pin,

journals and piston pin.

NOTE

• Top clearance = Width of the crushed plastigauge (2).

9Y1210824ENS0068US0

Cylinder Head Surface Flatness

1. Clean the cylinder head surface.

2. Put a straightedge on the cylinder head.

3. Measure the clearance with a feeler gauge at the 6 places (see

the figure).

4. If the measurement is more than the allowable limit, make it

straight with a surface grinder.

IMPORTANT

• Do not put a straightedge on the combustion chamber.

• Examine the valve recessing after you correct.

9Y1210824ENS0069US0

Top clearance

Factory specification

0.60 to 0.70 mm

0.024 to 0.027 in.

Tightening torque

Cylinder head screws

93.2 to 98.0 N·m

9.50 to 10.0 kgf·m

68.8 to 72.3 lbf·ft

(1) Plastigauge

(2) Crushed Plastigauge

(3) Scale

Cylinder head surface

flatness

Allowable limit

0.05 mm

0.002 in.

KiSC issued 03, 2016 A

Detailed Information for Kubota L3560 Owners Manual

Lists of information found in Kubota L3560 Owners Manual - Page 223

- 7. SERVICING [1] CYLINDER HEAD AND VALVES Top Clearance 1.

- 2. With the piston at TDC, use grease to affix three or four plastigauges (1) of a diameter 1.

- 5.0 to 7.

- 3. Take the piston to an intermediate position, install the cylinder head and tighten the head screws to the specified torque.

- 4. Turn the crankshaft so the piston goes through TDC.

- 5. Remove the cylinder head and compare the width of the crushed plastigauges (2) with the scale (3).

- 6. If they are out of spec, check the oil clearance of the crank pin, journals and piston pin.

- 1. Clean the cylinder head surface.

- 2. Put a straightedge on the cylinder head.

- 3. Measure the clearance with a feeler gauge at the 6 places (see the figure).

- 4. If the measurement is more than the allowable limit, make it straight with a surface grinder.

- 93.2 to 98.

- 9.50 to 10.

- 68.8 to 72.

- Top clearance = Width of the crushed plastigauge (2).

- Do not put a straightedge on the combustion chamber.

- Examine the valve recessing after you correct.