Fuel Injection Timing Correction Amount; Bearing Case Cover; different. Make sure that you use the correct one at the- Page 220

Kubota L3560 Owners Manual

Table of Contents

ENGINE

L3560, L4060, L4760, L5060, L5460, L6060, WSM

1-S73

Fuel Injection Timing Correction Amount

The difference A between the top dead center mark (1) and the

crank position sensor top dead center detection position mark (2) is

the correction amount for fuel injection timing.

Calculate the correction value referencing the following and

using a diagnostics tool, overwrite the injection timing correction

amount in the "data overwrite/confirmation".

(Remarks)

• 1 mm = 360 ° / (Flywheel Diameter × π)

(For example)

FD = 300 mm → 1 mm = 0.38 °

Correction amount (CA) = 0.38 × A (mm)

• If the crank position sensor top dead center detection position is

in front of top dead center, enter a negative value.

• If the crank position sensor top dead center detection position is

in back of top dead center, enter a positive value.

9Y1210824ENS0064US0

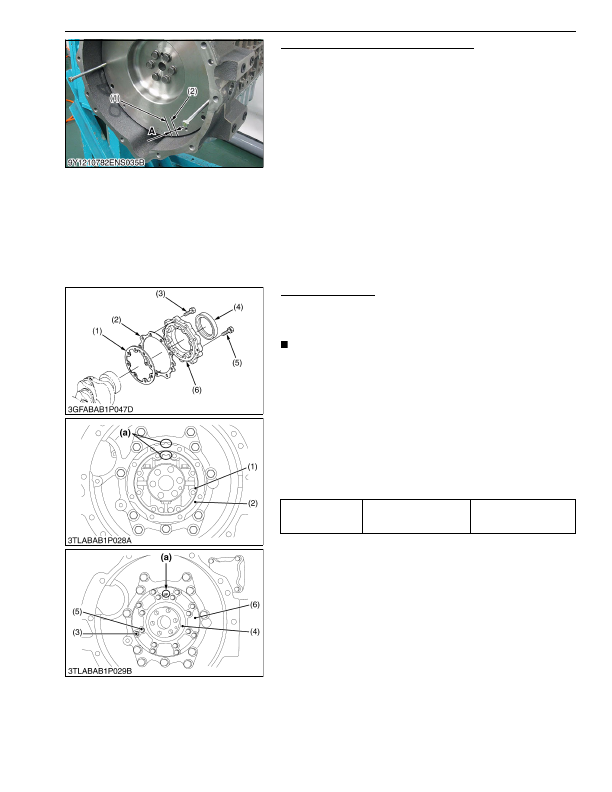

Bearing Case Cover

1. Remove the mounting screws of the bearing case cover. First,

remove inner screws (5) and then external screws (3).

2. Remove the bearing case cover (6).

IMPORTANT

• The length of inner screws (5) and external screws (3) are

different. Make sure that you use the correct one at the

correct position.

(When reassembling)

• Attach the bearing case gasket (1) and the bearing case cover

gasket (2) in the correct directions.

• Put the casting mark

"UP"

of the bearing case cover (6)

upward, then install the bearing case cover.

• Apply a thin layer of engine oil to the oil seal.

Then install the oil seal not to come off the lip.

• Tighten the mounting screws of the bearing case cover with an

equal force on the diagonal line.

9Y1210824ENS0065US0

(1) Mark for Top Dead Center

(2) Mark of Crank Position Sensor Top

Dead Center Detection Position

A: Correction amount (mm)

Tightening torque

Mounting screw of bearing

case cover

24 to 27 N·m

2.4 to 2.8 kgf·m

18 to 20 lbf·ft

(1) Bearing Case Gasket

(2) Bearing Case Cover Gasket

(3) Mounting Screw of Bearing Case

Cover

(4) Oil Seal

(5) Mounting Screw 1 of Bearing Case

Cover

(6) Bearing Case Cover

(a) Upside

KiSC issued 03, 2016 A

Detailed Information for Kubota L3560 Owners Manual

Lists of information found in Kubota L3560 Owners Manual - Page 220

- 1. Remove the mounting screws of the bearing case cover.

- 2. Remove the bearing case cover (6).

- 2.4 to 2.

- 1 mm = 360 ° / (Flywheel Diameter × π) (For example) FD = 300 mm → 1 mm = 0.

- If the crank position sensor top dead center detection position is in front of top dead center, enter a negative value.

- If the crank position sensor top dead center detection position is in back of top dead center, enter a positive value.

- The length of inner screws (5) and external screws (3) are different.

- Attach the bearing case gasket (1) and the bearing case cover gasket (2) in the correct directions.

- Put the casting mark "UP" of the bearing case cover (6) upward, then install the bearing case cover.

- Apply a thin layer of engine oil to the oil seal.

- Tighten the mounting screws of the bearing case cover with an equal force on the diagonal line.